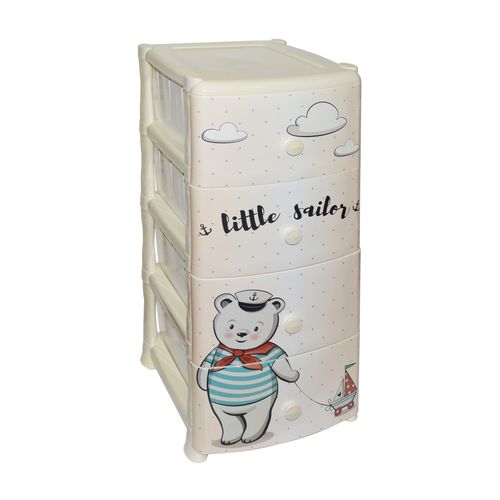

Cut your production costs and boost sales by choosing the innovative IML (in-mold label) technology!

- Compliance with Walt Disney standards

- Strict SLA parameters for quality & lead time

- Prompt delivery to any regions of Russia & CIS

Apply for IML testing, and our manager will contact you within 30 minutes for details.

The first

mastered

IML technology in Russia.

we have the most extensive

experience.

mastered

IML technology in Russia.

we have the most extensive

experience.